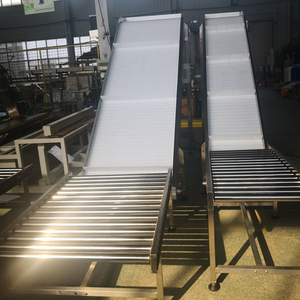

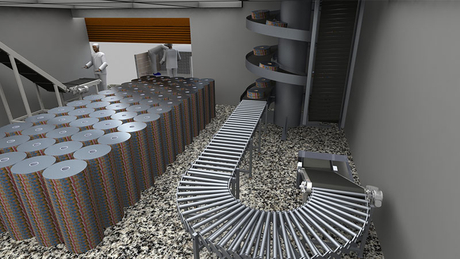

Belt conveyor systems are the most commonly used conveyors for items with irregular bottom surfaces and loose materials that need to be moved at A certain speed from point A to point B. A belt conveyor consists of a frame with rollers at both ends of the frame and the conveyor belt rotates around these pulleys. One pulley is a powdered pulley that pushes the belt and the material on the belt forward. Powdered pulley is called driven unit, no power pulley is called idler pulley unit.

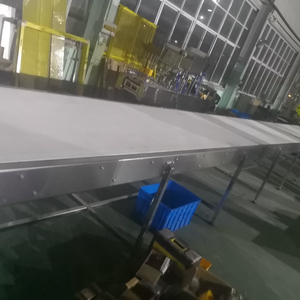

Material with anti-static, PU, PVC, food grade belt; Thickness 2mm, 3mm, 5mm; For the transfer of the second package product; Cost effective

Width can be customized, the maximum width of the general belt conveyor is 1500mm;

The PVC belt conveyor is the standard belt in the food industry and can be used for basic applications in food processing and handling.

PVC has grown into the third most widely produced plastic, known for its durability and ease of use.

PVC coated conveyor belt is most suitable for material handling, baking production applications, meat, fish and dairy processing.

These anti-static strips provide good chemical resistance and resist hot water and steam as well.

Due to limited wear resistance and limited resistance to solvents, oils and greases, PVC tape is best suited for processing fruits and vegetables and simple operations with limited special requirements.

For those who do not know the specifications of their food processing, PVC belt is a reliable option and offers a price advantage over other conveyor belts.