People talking linear filling machine, always said liquid filling machine, but we design and produce linear powder filling machine, which maximum have 4head linear type with dust collector system.

Compare with 1head powder filling machine, 2-4head powder filling machine speed higher, and price cheaper than high speed rotary powder filling machine.

Depending on your products to be filled, it will be equipped with the right pump. Set up with a magnetic or mass flow meter, this automatic filling machine is equipped with powder tank that is appreciated for it's dust collector system. Very precise, the2-4head powder filler ensures the automatic centering of the products and can count for an accuracy of 0.5% and a rate of filling up to 5000gram. Its frame is made of 304L stainless steel.

Advantages

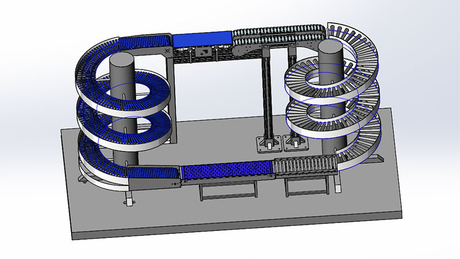

- 2 to 4 filling nozzles (plungers optional)

- Dust collector system

- Easy management via touch screen

- Automatic product centering Characteristics Filling accuracy:+/- 0.5%

- Chemical industry - Cosmetics industry - Food processing industry

Metering Model: Auger dosing with weighing feedback and rejecter, all safety switches. Cans lift and vibration when filling.

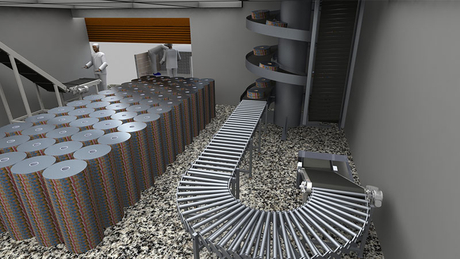

◇Cans Feeding model: by screw

◇Filling Range:≤5000g

◇Filling Accuracy:

High speed mode: ±0.3-1%,

High accuracy mode: ±1-2g

(depend on product property and filling speed)

◇Speed:

High speed mode: Max 120 cans/min

High accuracy mode: Max 60 cans/min

(speed depend on shape of container, product property and filling weight)

◇Container Type: tin can, glass bottle, plastic jar, paper can, etc.

◇Hopper Volume:50L (horizontal semi open)

◇Container Size: D:Φ50-200mm,H:80-270mm

◇Power: 3-phase 380V 50Hz

Material: stainless steel 304

◇Machine weight: 750Kg

Main Components

PLC siemens S7-1200

touch screen siemens ktp900

*Servo motor: Panasonic

* Inverter: Schneider

* Bearing: SKF

*Pneumatic cylinder: SMC or AIRTAC

*Fiber Sensor: Banner

*Lower Voltage Electricals: Schneider,etc