Ribbon mixer consist of dirven parts, U shape cylinder, the outer ribbon push the raw material from both end to middle side, meanwhile, the inner blade-ribbon push raw material from middle to both side, on blate, different angle also carry raw material flowing in different direciton; with this opposite processment, the raw material be mixing and shearing very well and quickly.

The motor and reducer assmbled on side type, chopper design is one choice if client required. also heating or cooling jacket can be added. material MS & SS both available. working volume can offer 0.5m3 to 15m3.

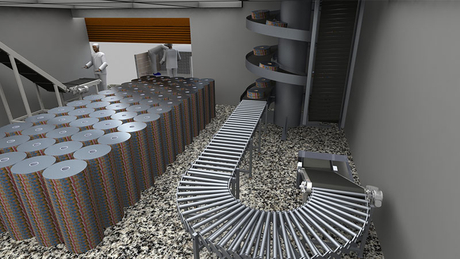

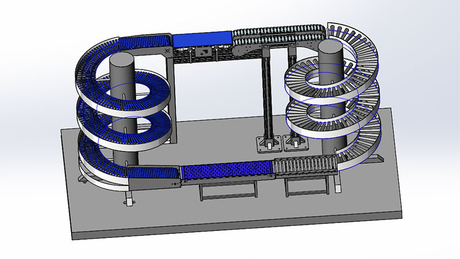

the hopper bin, we can offer, 5L, 10L, 15L, 20L till 500L; with screw feeder auger size 12(1-3g), 14(2-10g), 16(3-12g) ,21(8-30g) ,25.4(15-60g), till 89(1000-3000g) 102(1500-5000g), 159(55000-20000g).

the powder filling machine, designed under newest version of GMP standard. height less than 2meter, with filling, weighing, sealing, sewing, and conveyor system together.

calculating mode is gross weight filling;

filling mode have double screw, double cylinder, double vibrator chute.

package weight 10-25kg; the extra 20--50kg customized.

speed less than 5bags per minute.

power supply 380V/415V/ 220V/ 50hz/60hz

filling power need maximum 4kw;

atmospheric pressure required 6-8kg/cm2