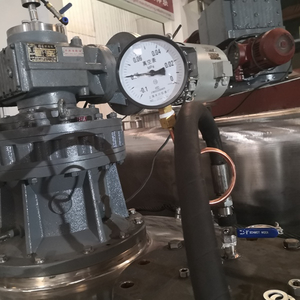

The conical screw mixer consists of one long screw and one short screw. The long screw lift the material up and fall down with gravity. At the same time, the screw arms run slowly by means of revolution. This type of mixer is widely used for powder mixing and powder mixing with little liquid, without residues and low energy consumption. It could be tail designed for heating, cooling, positive pressure and vacuum function.

Advantage: Small dimension, very gentle mixing, respect for material used. Lower energy consumption, delicate action on material, can add heating jacket, hold temperature.

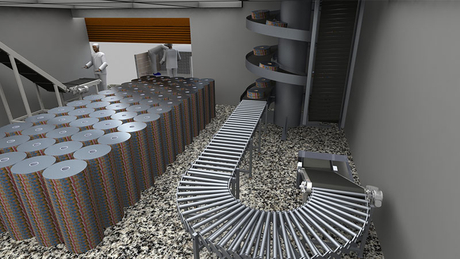

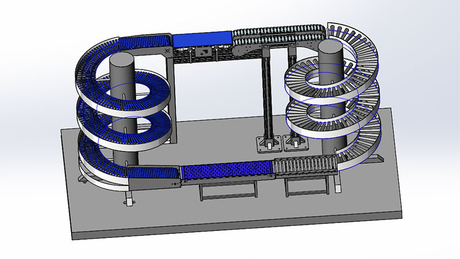

Conical mixer / vertical cone mixer and powder blender (AM) Ideal mixing quality for dry, moist and viscous materials at variable filling levels The spiral mixing blade of the conical mixer initiates a three-dimensional flow of the mixing goods; creating a helical upward movement on the periphery and downward flow in the centre. This blender guarantees very good mixing results and complete discharge. It can be used as powder blender for dry powder, wet suspensions as well as liquids, paste and dough. The vertical mixer can be designed to conform with FDA and 3-A Sanitary Standards to be used as a sterile mixer and reactor which also meets GMP requirements. Further characteristics of the powder blender and conical mixer

• If the mixing process requires agglomeration, high speed cutting rotors can be installed.

• The mixing device is driven from the top, using only a single top bearing.

• The conical mixer meets all industry standards for surface finish, including sanitary and pharmaceutical requirements.

• Jacketed and vacuum rated versions are an ideal vacuum dryer or reactor.