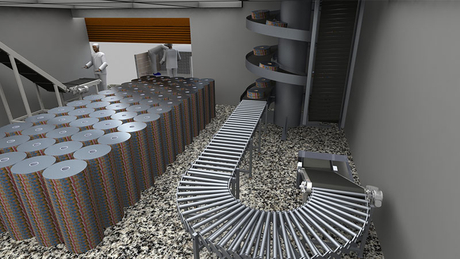

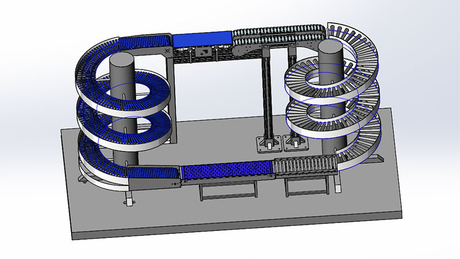

Mixtures are lifted by two fast rotating asymmetric screws in the vessel, which makes two asymmetric mixtures flows moving up helically along vessel wall. These two screws, rotating around the axis of the vessel, it makes some of the mixtures around screw drop into envelope line of the helicoids, part of the material is lifted up due to dislocating movement, and the rest drops out of the helicoids. Due to this complicated movement in the mixer, all the materials inside the vessel are mixed with continuously renewing and diffusing. These two material flows lifted to upper of the vessel will move and merge together in the center of the vortex, this result a downward material flows to replenish the cavity in the bottom of the vessel. All these up and down movements form into a countercurrent circulation.Good mixing effect in short time could be realized. Spraying functioned by pipe and nozzles make when blending arm moving make good effect for spraying.

This series mixer is well adaptable with the mixtures: overheating will not be occurred tothe heat sensitive materials; crushing and grinding will not be happened to granular materials; no segregation or delaminating will be happened to the mixtures which have different particle size and badly mismatched specific gravity; it is also suitable for the mixing of a great variety of materials, including particles, fibers or flaps, despite of coarse particles, fine grains or superfine powders.

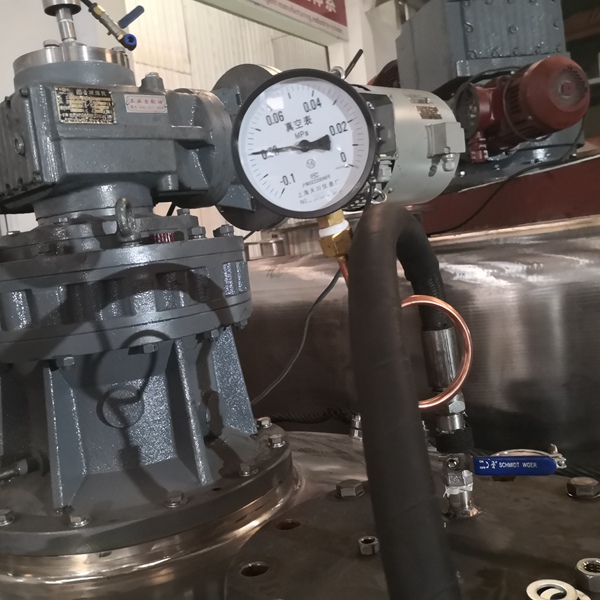

Spraying system Consisted of spraying nozzle and pipes, spraying parts system is equipped on distribution box in flange way and works with blending arm. Nozzle and parts are joint together in flexible way to ease the maintenance.