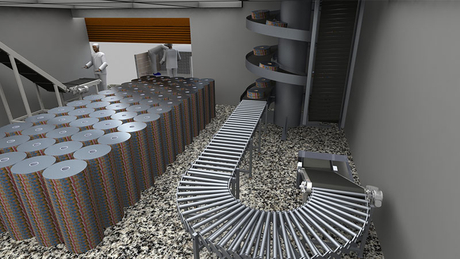

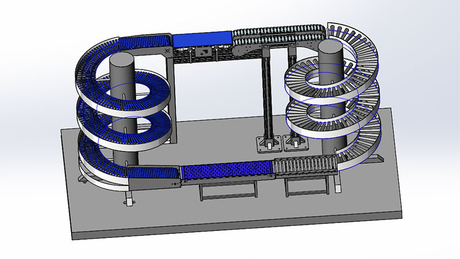

Ribbon mixerBasic Information

a)Total volume: 1500L

b)Model: GPH-1.5

c)Loading factor: 30%-70%

d)Working Capacity: 450L-1050L

e)Capacity: 225kg-525kg/batch (if bulk density 0.5kg/l)

f)Working Temperature: Ambient

g)Design Pressure: -0.8 barg

h)Mixing assembly: Vertical Ribbon Agitator

i)Working Type: Batch

j)Installation: Indoor

2)Processed material

a)Material to be mixed: Baby Powder

b)Bulk density: 0.4-0.5kg/l

c)Particle size: N/A

d)Liquid additives: Yes (2-3%)

3)Construction material

a)Material Contact Part: Stainless Steel 304

b)Non-contact Part: Stainless Steel 304

4)Surface treatment

a)Material Contact Part: #300 (grit) Polish (Ra 0.8)

b)Non-contact Part: Matte Polish

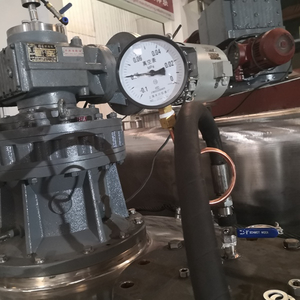

5)Seal Part:

a)Main Shaft: Mechanical Seal

b)Chopper: Labyrinth Seal + Air Purge

6)Drive Unit x 1:

a)Main Shaft Motor: 18.5KW

b)Brand: Siemens

c)Insulation Class: F

d)Main shaft speed: 50rpm

e)Gear Reducer Type: V3HV5

f)Brand of Gear Reducer: GUOMAO

g)Power supply: 415V, 3P, 50Hz

h)Start the mixer with load

7)Chopper x 1:

a)Power: 4KW

b)Brand: S&L

c)Insulation Class: F

d)Main shaft speed: 1440rpm

e)Chopper Type: Tulip Type

f)Power supply: 380V, 3P, 50Hz

8)Nozzle List: according to confirmed drawing

9)Discharge assembly x 1:

a)Pneumatic Operated Flap Valve

b)Discharge Port Size: DN250

c)Stainless Steel 316L

d)Solenoid Valve: 24VDC