Design Data

1) Power supply: 415V, 3P, 50HZ

2) Processed raw material

a) Raw material to be mixed: tobacco powder

b) Average bulk density: 0.6kg/l

c) Liquid additives: 10%

Construction material

1) Contacted part with raw material: SS304

2) Non-contacted part with raw material: CS

3) Jacket: SS304

Thickness

1) Top cover: 6 mm

2) Vessel: 10 mm

3) Jacket: 8 mm

4) Endplate: 16 mm

Surface treatment

1) Internal: mirror polishing

2) External SS part: sandblasting

3) External CS part: painting

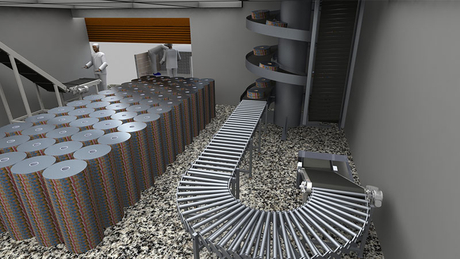

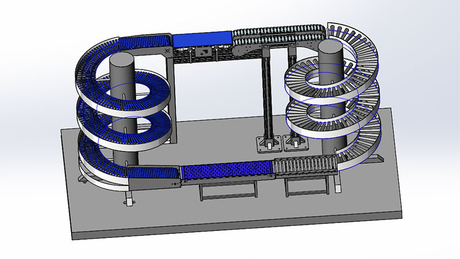

Equipment description: ribbon mixer, paddle type

1) Model: WLDH-6

2) Total volume: 6000 L

3) Loading factor: 0.4~0.6

4) Working volume: 2400~3600 L

5) Batch capacity: 1440~2160 kg @ 0.6 kg/l

6) Overall dimension (L×W×H): ~5000×1900×2800 mm

Driving assembly

1) Motor

a) Power: 55 KW

b) Electric protection class: IP55

c) Special requirement: variable frequency motor

d) Brand: Siemens brand

2) Reducer

a) Model: V3HH9

b) Brand: Guomao Brand

3) Motor and reducer is belt connection

4) Main shaft

a) Speed: 23 rpm

b) Seal: packing seal (food grade Teflon packing), with water cooling device

c) Bearing brand: Chinese brand

Nozzle list

1) Feeding port (a)×1: DN350, PN10 HG20592, with pneumatic butterfly valve DN300

2) Exhaust port (b)×1: 12”, TC with blind cover

3) Hot air inlet (c)×1: DN100, TC with blind cover

4) Hot air outlet (d)×1: DN100, TC with blind cover

5) Man hole (e)×1: Ø500 (Pressure type), S&L standard, with safety grid and limited switch 24V

6) Discharge port (f)×1: DN350, PN10 HG20592, with pneumatic flap valve, short stub and pneumatic butterfly valve DN300, solenoid valve 24V, final discharging port is DN300

7) Oil inlet (g1-7)×7: DN40, PN10 HG20592, g5 with flange type rotary joint, details of joint venture as below:

a) Highest speed: 180 rpm

b) Highest pressure: 1.8 Mpa

c) Highest temperature: 340℃

d) Suitable working media: heat transfer oil

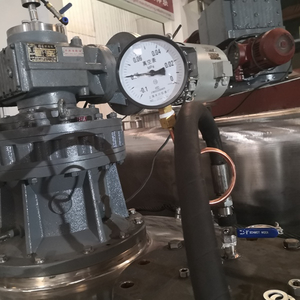

e) The fix type shall be as following pictures shows

8) Oil outlet (h1-5)×5: DN40, PN10 HG20592

9) Oil outlet (i1-2)×2: DN40, PN10 HG20592

10) Vacuum meter port (j)×1: 1/2’’, BSP, with vacuum meter

11) Inlet (k)×1: DN40, PN10 HG20592

12) Safety valve port (l)×1: DN40, PN10 HG20592, safety valve×1

13) Drain hole (m)×1: DN40, PN10 HG20592

14) Drain hole (n)×1: DN40, PN10 HG20592

15) Temperature probe (o1-2)×2, S&L standard

16) Spare port (p)×1: 4”, TC with blind cover

17) Spare port (q)×1: DN40, PN1.0-GB/T5010

18) Pneumatic sampler (r)×1: S&L standard

Vessel

1) U shaped vessel

2) Top cover is doom type, bolted with vessel

3) Blending assembly: paddle

4) Design pressure: -1~0 bar

5) Design temperature: <280℃

6) Working temperature: 240℃

7) End plate welded with vessel

8) Sealing gasket

a) Vessel with top cover: PTFE joint sealant

b) Discharging box with short stub: PTFE joint sealant

c) Discharging door with vessel: silicon rubber

Jacket

1) Design pressure: 5 bar

2) Working pressure: 3 bar

3) Design temperature: 280℃

4) Working temperature: <280℃

5) Insulation

a) Material: rock wool

b) Thickness: 50 mm

c) Outside layer material: SS304 (thickness is 2mm)

Supply scope

1) Including mixer with motor, reducer, discharging valve and insulation

2) Including air control box

3) Excluding electric control panel