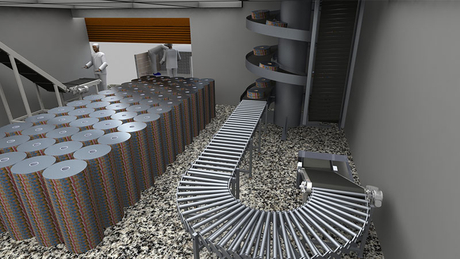

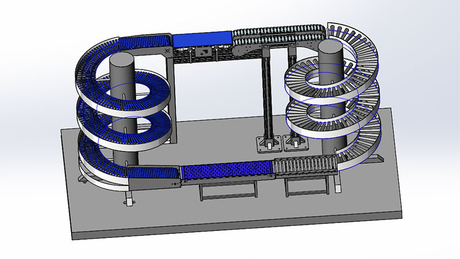

Ribbon mixer consists of U shape shell,double ribbons and drive unit The exterior ribbon transfers raw material from the two ends to centre while the interior ribbon moves the material in opposite in form of counter-current movement. Ribbons can be changed into paddles,and chopper is optional for different materials. The top cover can be concave for pressure application,or full open way to ease the cleaning. The advantage of ribbon mixer is wide application,high mixing precision,short mixing time and large loading ratio.

Advantage: middle mixing time, respective mix processing, lower maintenance and investment cost.

Ribbon mixer will process free flowing material within U shaped trough. Horizontal agitator moves the material in a highly balanced axial and radial flow pattern, ensuring mixed consistency and a high level precision.

We design and manufacture a full range of sizes for the ribbon mixer, from 100L to 20cubic meters.