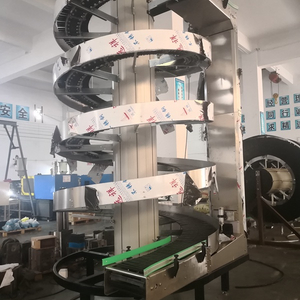

Width 600mm, have full supportation frame stainless steel 304; bearing support frame is food grade, thickness is 4mm, better than most factory which use 2mm, after keep running 6months, need to maintance again; 4mm too much better in mass production.

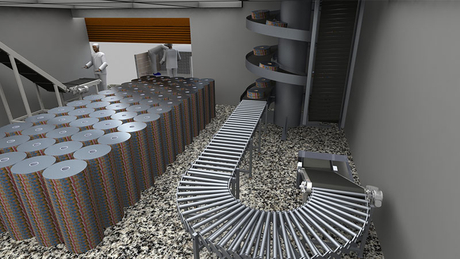

this cooling spiral conveyor use for meat/pork cooling frozen under -15-20celsius degree, after cutting raw material, this spiral conveyor use in separate room, which temperature lower, whole meat running on conveyor to this spiral conveyor, material can buffer stay on this machine more than 30minutes; very suit for mass production.

cooling spiral conveyor advantage: quickly frozen product, give buffer stock area, whole production line no need stop, continously frozen, saving manpower, and electrial/oil cost.

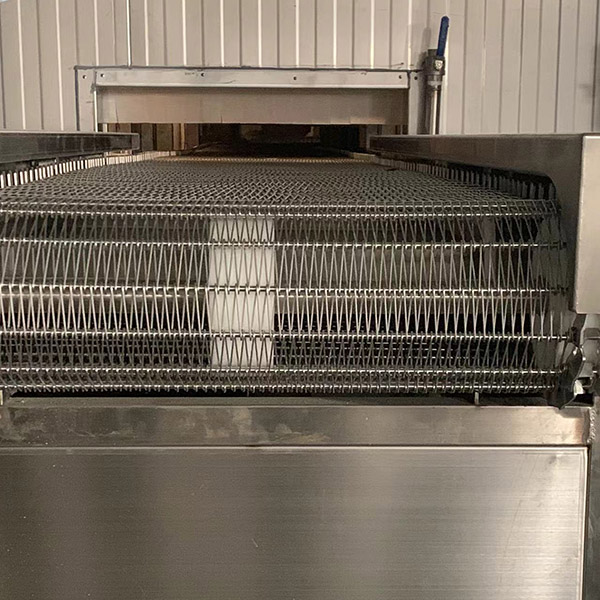

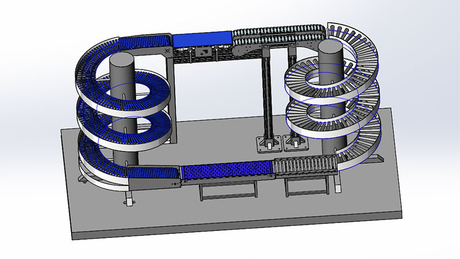

The main frame are composed of SUS304 stainless steel. The guide rail support bar is made of 30mm diameter solid stainless steel round bar, with high bending strength. The connection between the guide rail and the support bar is not traditional welding, but bolt and nut connection, with high installation accuracy. The stainless steel guide rail is covered with wear-resistant ultra-high polymer composite polyethylene material, which can fully guarantee the minimum friction coefficient between it and the stainless steel conveyor belt. The cage column support, shaft, transmission gear and chain of the quick-frozen device are all made of SUS304 stainless steel, which meets the requirements of QS, FDA and other food certification.

High-strength conveyor belt made by imported special equipment, with smooth and beautiful surface and long service life. The diameter of the piercing rod is 5mm, and the thickness of the chain piece is 2.5mm, so the frozen products can be placed directly on the conveyor belt. The mesh belt is of internal shrinkage type, with retaining edge on both sides of the chain piece, the height of the edge is 12mm, the mesh belt is made of food grade SUS304 stainless steel, which can ensure the product hygiene requirements.

The spiral quick-freezing device drive is divided into two parts: the main drive and the auxiliary drive. The main drive provides the power for drum operation and the main power in the whole system. We choose the first-line brand GM reducer with reliable performance to fully guarantee the reliability of use; the auxiliary drive adopts German NORD reducer as a kind of mesh belt automatic tensioning device to adjust the tension of the whole mesh belt to ensure that the conveyor belt reaches the most reasonable low tension matching under various temperature and different load conditions.

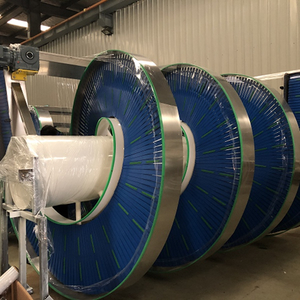

The drum is welded with high strength stainless steel structure, and our company adopts the whole stainless steel square tube welded on the outer ring to ensure the torsional strength of the rotating cage. The upper and lower connecting flange of each cage is corrected for coaxiality to ensure that the upper and lower bearings are coaxial after installation. The rotating cage sprocket is calibrated at the same level with micrometer to reduce the wear and tear during the operation of the big chain.

Safety guards (imported from Denmark)

(1) Belt tensioning mechanism adjustment sensor

If the belt is too long or too short, the belt length adjusting sensor will shut down the quick-freezing device immediately.

(2) Conveyor belt roll-up sensor

Two belt roll-up sensors are installed on the first pillar and the pillar opposite to it. If the outer side of the mesh belt lifts up due to increased tension, this sensor immediately issues a command to shut down the spiral quick-freezer drive system.

Single spiral device with material description

| No. | NAME | APPLIANCE |

1、transmission system |

Belt | (1) | Mesh belt structure | Stainless steel mesh belt for spiral |

(2) | Wire material | High strength SS 304 spring steel wire mesh |

(3) | Chain piece material | SS 304 stamping chain piece |

(4) | Mesh belt parameters | Thickness of chain link 2.5mm, diameter of wire 1.5mm, center distance of wire 10mm, height of retaining edge 12mm, diameter of piercing rod 5mm |

Transmission System | (1) | Inverter brands | Schneider |

(2) | Main drive reducer | Guomao |

(3) | Secondary drive reducer | Germany NORD |

(4) | Mesh belt running track | 40×5 304 stainless steel flat bar, bolt and nut connection |

(5) | Mesh belt running track support bar | SUS304, φ30 drawn circle |

(6) | Rotating cage upper and lower bearings | Japan NSK |

(7) | Rail wear strips | Ultra High Polymer UHMWPE Polyethylene |

Rotary Cage | (1) | Main rotating cage shaft | SUS304 tube |

(2) | Main column | SUS304 SS square tube |

(3) | Rotary cage square tube wear bar | Ultra High Polymer UHMWPE Polyethylene |

(4) | Rotary cage drive type | SS chain sprocket drive system |

(5) | Drive Chain | SS304 |

(6) | Drive sprocket | SS304 |

2、Electrical control section |

Electrical and control systems | (1) | Control penal | All SS electric control cabinet |

(2) | Touch Screen | WEINWIEW |

(3) | PLC | France Schneider |

(4) | Electrical component brands | France Schneider |

(5) | Power supply configuration | 380V/50HZ,3phrase |

3、Safety System |

Safety and protection devices | (1) | Rotating cage mesh with anti-turnover protection monitoring system | Denmark imported proximity switch automatic detection |

(2) | Over-length and over-short detection system for webbing | Denmark imported proximity switch automatic detection |

(3) | Large chain drop monitoring alarm device | Denmark imported proximity switch automatic detection |